The product is designed as a new type of aluminum foil current collector with uniform coating of graphene on its surface. Based on the excellent electrical conductivity and two-dimensional laver structure of graphene, the ultra-thin layer with a thickness of less than 0.5pm on the surface of aluminum foil has high electrical conductivity, which significantly reduces the interface resistance. and thus improves the adhesion between active materials and aluminum foil. Such a current collector is beneficial to the rate capability and cycle life of battery and supercapacitors. Its comprehensive performance is much better than those of other aluminum foils based on conventional carbon materials. it can replace traditional aluminum foil and corrosion aluminum foil for Li-ion batteries and supercapacitors.

| Place of Origin |

Shenzhen, China |

| Temper |

Soft |

| Treatment |

Coated |

| Alloy |

Alloy8011 |

| Brand Name |

NSfoil |

| Model Number |

NSPAF-005 |

| Name |

Porous Aluminum Foil |

| Certificate |

ISO9001 |

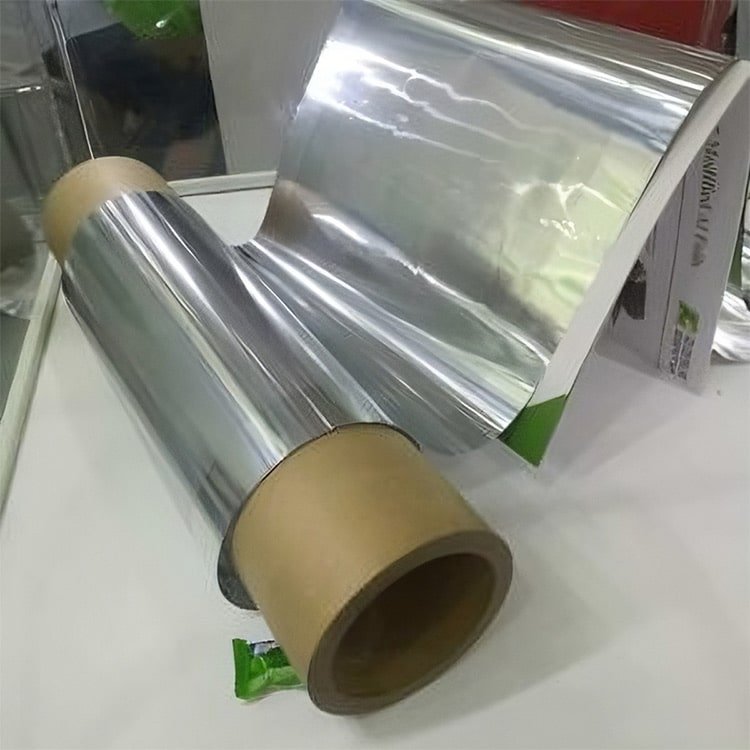

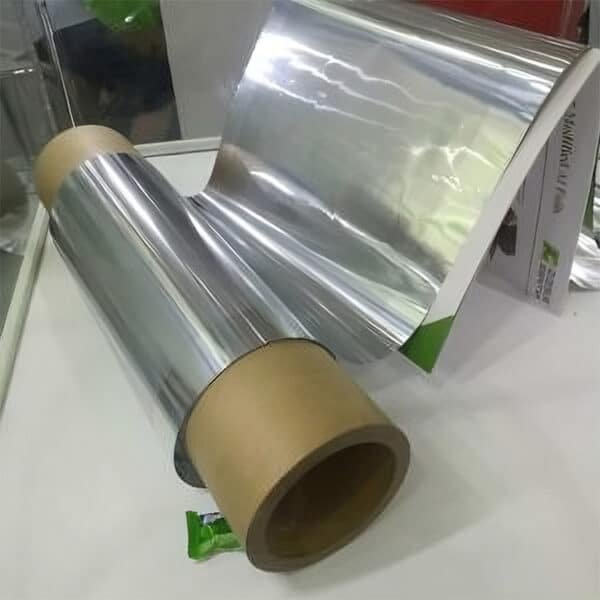

| Color |

Silvery |

| Usage |

Lithium Battery Electrode |

| Application |

Li ion Battery |

| Material |

99.9% Aluminum Foil |

| MOQ |

5 square meters |

| Width |

customized |

| Packing |

Carton |

Application Areas:

Li-ion Batteries

Supercapacitors

Specifications & parameters:

Appearance: Dark gray coating.

Coating Thickness (double side)/um: Typically 0.5

Areal density (double side)/mg cm-2: 0.04~0.1

Usage Instructions:

GC-foil can be directly used as current collector in Li-ion batteries or supercapacitors.

GC-foil is suitable with different coating methods. When coating, the humidity should be controlled below 30%.

When using ultrasonic welding to weld the tab on, it is suggested to set the power 10% higher than that for ordinary aluminum foil.

It is highly hygroscopic. Do not open the vacuum package before use. Once opened, it should be properly stored in a vacuum environment at room temperature after vacuum drying at 40-60C.

Features

Micro porous aluminum foil fluid collectors are widely utilized by various industries due to their diverse set of features and capabilities. Here are a few key aspects of these collectors:

1. High Porosity: Micro porous aluminum foil fluid collectors have an extremely porous structure that enables efficient fluid collection and distribution. Their interconnected network of small pores enables fluids to pass quickly through, aiding drainage processes while offering effective separation solutions.

2. Superior Capillary Action: Aluminum foil’s microporous structure provides outstanding capillary action that enables fluid absorption and retention, making it especially helpful in fuel cells, batteries and medical devices that require fluid retention or wicking applications.

3. Uniform Pore Size Distribution: Micro porous aluminum foil fluid collectors feature uniform distribution of small-sized pores to provide consistent fluid flow without any clogging or uneven distribution of fluids. This uniformity helps ensure consistent fluid movement while avoiding any clogs or uneven distribution of fluids.

4. High Surface Area: Micro porous structures provide a large surface area for fluid interaction, increasing efficiency in collection and separation processes. Furthermore, increased contact between fluid and collector enables more effective fluid management practices.

5. Lightweight and thin: Micro porous aluminum foil fluid collectors are lightweight and thin, making them suitable for applications that have minimal weight or space requirements. Their low-profile design makes integration into devices or systems seamless and straightforward.

6. Corrosion Resistance: Aluminum foil has natural corrosion-resistance, making it an excellent material choice for fluid collectors in contact with highly acidic liquids or environments. This property guarantees its longevity and reliability even under demanding circumstances.

7. Thermal Stability: Micro porous aluminum foil fluid collectors offer excellent thermal stability, making them suitable for applications involving heat transfer or exposure to elevated temperatures without experiencing significant degradation. This property makes them an invaluable choice.

8. Chemical Compatibility: Micro porous aluminum foil fluid collectors can often be made compatible with an extensive range of fluids and chemicals, enabling their use across numerous applications. They have the strength to withstand most common chemicals for reliable performance and long term durability.

9. Customizability: Micro porous aluminum foil fluid collectors can be customized in terms of thickness, pore size and overall dimensions to meet specific application needs. This adaptability enables fluid management processes and performance improvements.

10. Versatility: Micro porous aluminum foil fluid collectors find applications across a range of industries, such as energy storage, filtration, medical devices, aerospace, automotive and electronics. Their applications include liquid or gas transport and distribution as well as humidity control and separation of substances.