| Application |

Lithium Battery |

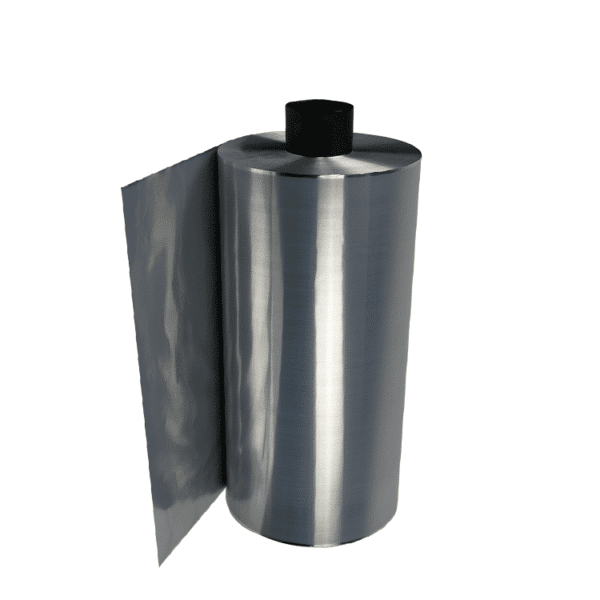

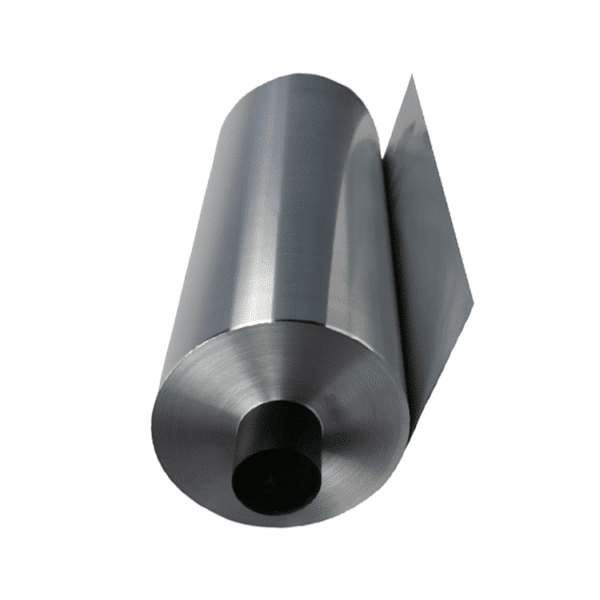

| Shape |

Roll |

| Base material thickness: |

10-20 μ m |

| Base material: |

aluminum foil, copper foil |

| Place of Origin |

Shenzhen, China |

| Temper |

Soft |

| Treatment |

Coated |

| Color |

black, gray |

| Brand Name |

NSfoil |

| Model Number |

NS-EAF-005 |

| Product name |

For Etched Aluminum Foil Collector Supercapacitors |

| Coating method: |

single coating, double coating |

| Inner diameter of pipe core |

76mm |

| Warranty |

12 Months |

| Material width |

Customized |

| Packaging: |

Wooden Box |

| Shape |

Roll |

| MOQ |

10kg/roll |

For Etched Aluminum Foil Collector Supercapacitors can be uniformly coated on the surface of aluminum foil current collector by using gravure coating technology. The thickness of coating layer can be adjusted by gravure roller mesh and coating speed.

Generation of a small amount of precipitation after long term storage is allowed. Please stir till homogeneously dispersed before use.

It should be used immediately after opening Once opened. it should be stored in sealed containers and used within one month

The suggested coating thickness (double sides) is<1um (double sides areal density of 0.08-0.1 g/cm2) . We can manufacture the graphene coated foil according to customer’s requirement.

Features

1. High surface area Collectors of aluminum foil etched are characterized by a larger surface area in comparison to the smooth foils of aluminum. They are intentionally roughened by etching procedures, which result in more active areas for electrode deposition of the material. The increased surface area allows for increased capacitance as well as improved storage capacity of energy.

2. Conductivity enhancement: Etched aluminum foil collectors possess outstanding electrical conductivity. Etching doesn’t alter the conductivity of aluminum foil, which ensures efficient charge transfer inside the electrodes of the supercapacitor. This feature allows quick charging as well as discharging that result in higher capacity power.

3. Low resistance The etched surface on aluminum foil collectors lowers the resistance of contact between electrodes and collectors. This decreases the resistance inside the supercapacitor. This results in an increase in energy efficiency as well as a reduction in energy losses in discharge and charge cycles.

4. Stability of the mechanical The collectors with etched aluminum foil have a high mechanical strength and stability. They can withstand the pressure and strain that comes with supercapacitor operation and assembly without damage or deformation. This stability of the mechanics assures the long-term durability and reliability of the device.

5. The aluminum foils are naturally resistant to corrosion and provide protection against chemical attack within the supercapacitor atmosphere. Etching can further increase the resistance to corrosion of the surface by removing contamination or surface impurities that can cause corrosion. This is a significant factor in the durability and efficiency of the Supercapacitor.

6. Customizability Aluminum foil collectors with etched edges can be custom-designed in terms of the thickness, pore size and surface morphology to satisfy the specific requirements of a supercapacitor. This flexibility permits enhancement of the electrode’s performance, such as capacitance, power density along with overall performance.

7. Cost-effective Aluminum foils are affordable compared with other electrode materials utilized in supercapacitors, like graphene or carbon nanotubes. The process of etching that creates roughened surfaces is an efficient method for cost. This allows etched aluminum foil collectors to be the most cost-effective option for manufacturing supercapacitors.

8. Scalability Collectors made of etched aluminum foil can be used in manufacturing processes that can be scaled and are therefore suitable for production at a large scale of supercapacitors. The easily accessible and processed aluminum foil permits effective and cost-effective production in mass quantities of supercapacitors.

9. Stability of thermal energy: Etched aluminum foil collectors have excellent thermal stability, which permits the use of them in capacitors which are able to operate at temperatures that exceed. The aluminum foil can handle the heat produced in charge-discharge cycles with no major degradation, and maintain its overall efficiency and durability for the high-performance capacitor.

10. A wide range of applications The etched aluminum foil collectors are used extensively in many applications, such as energy storage systems as well as hybrid vehicles consumer electronics as well as renewable energy and industrial applications. They are unique in their features, making them ideal for demanding applications which require a the highest power density, speedy charging, and a long cycle times.

Advantages

◎ Improve the surface tension and increase the adhesion Lithium-ion batteries for electric vehicles between the Al foil and the active material.

◎ Decrease the using amount of binder for the electrode, enhance energy density of the battery ,and lower the cost of the electrode production.

◎ Protect the Al current collector from surface corrosion and oxidation.

◎ Reduce interfacial resistance and internal resistance of the cell.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise Lithium ion battery in water system the pass rate of the cell; Increase the consistency and cycling life of the cell and lower the cost of the production