Electrochemical corrosion foil is a specialized type of foil that is designed to resist the effects of corrosion caused by electrochemical reactions. Here are some of the main features of electrochemical corrosion foil:

Electrochemical corrosion foil is a specialized type of foil that is designed to resist the effects of corrosion caused by electrochemical reactions. Here are some of the main features of electrochemical corrosion foil:

Electrochemical corrosion foil is a specialized type of foil that is designed to resist the effects of corrosion caused by electrochemical reactions. Here are some of the main features of electrochemical corrosion foil:

Electrochemical corrosion foil refers to a type of foil designed to resist or protect against electrochemical corrosion. Some features and characteristics of electrochemical corrosion foil:

1. Corrosion Resistance: Electrochemical corrosion foil is highly resistant to corrosion caused by electrochemical reactions such as oxidation or reduction processes. Typically made of materials which exhibit inherent corrosion resistance such as stainless steel or corrosion-resistant alloys.

2. Protective Coatings: Electrochemical corrosion foil can benefit from having a protective coating applied to its surface for extra corrosion protection, acting as a barrier between its metal substrate and harmful substances like moisture or chemicals that could potentially corrode it.

3. Passivation: Electrochemical corrosion foils often undergo a process known as passivation, in which an oxide layer forms on their surface to act as a protective barrier and reduce the likelihood of corrosion initiation and propagation.

4. Chemical Stability: Electrochemical corrosion foil has high chemical stability, withstanding exposure to acids, bases and salts for years without becoming compromised or vulnerable to corrosion.

5. Superior Conductivity: Many electrochemical corrosion foils boast outstanding electrical conductivity, making them suitable for applications where both corrosion resistance and electrical conductivity are essential – such as electronic components or electrical connections.

6. Temperature Resistance: Electrochemical corrosion foil can withstand elevated temperatures without suffering significant degradation to its corrosion-resistance capabilities, making it suitable for applications where temperatures exceed certain thresholds. This makes electrochemical corrosion foil ideal for use where elevated temperatures exist.

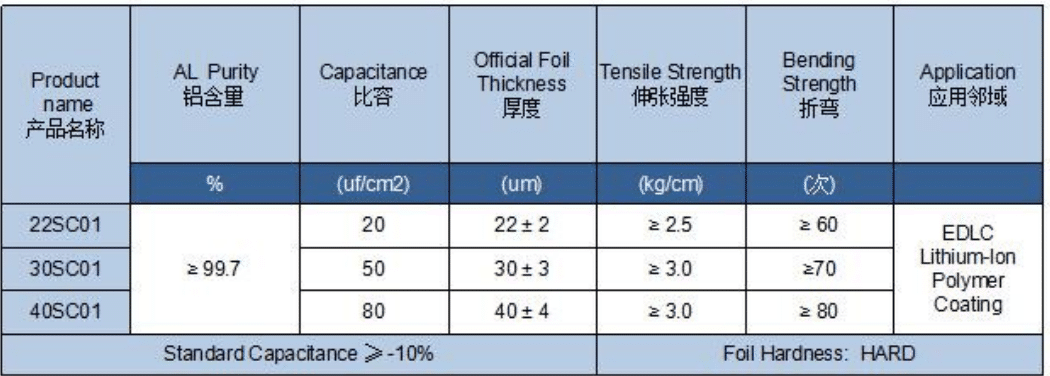

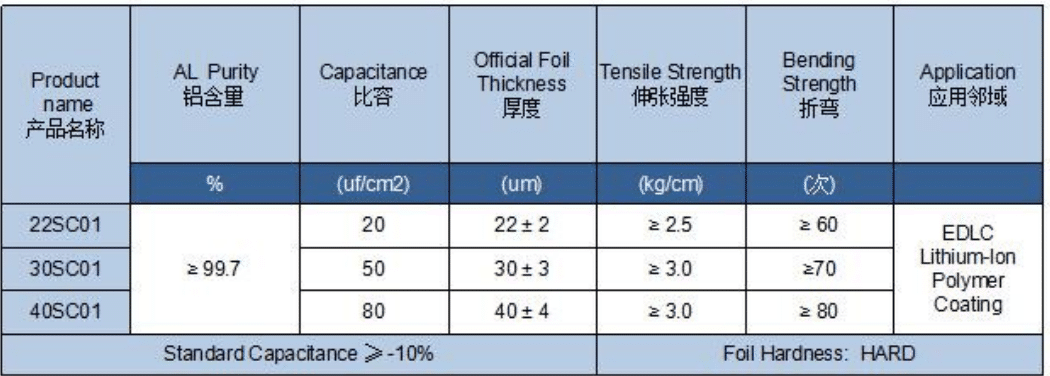

7. Good Mechanical Properties: Electrochemical corrosion foil typically boasts excellent mechanical properties, including high tensile strength and flexibility, that facilitate easy handling, forming, and installation in various applications.

8. Customizability: Electrochemical corrosion foil can be customized in terms of size, thickness and composition to meet specific application needs. This versatility enables adapting it to various environments and conditions.

9. Longevity: Electrochemical corrosion foil has been designed for long-term service life and provides durable protection from corrosion over extended periods.

10. Versatility: Electrochemical corrosion foil has wide-ranging applications in industries as diverse as aerospace, automotive, marine, chemical processing, electronics and construction – any where corrosion protection is essential for performance or longevity of components or structures.

◎ Improve the surface tension and increase the adhesion Lithium-ion batteries for electric vehicles between the Al foil and the active material.

◎ Decrease the using amount of binder for the electrode, enhance energy density of the battery ,and lower the cost of the electrode production.

◎ Protect the Al current collector from surface corrosion and oxidation.

◎ Reduce interfacial resistance and internal resistance of the cell.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise Lithium ion battery in water system the pass rate of the cell; Increase the consistency and cycling life of the cell and lower the cost of the production

NSfoil was established in 2012 in Foshan city, guangdong province,which is a high-tech national high-tech enterprise integrating the research,development, production and sales of functional current collector materials.

Building 55, Lianchuang Technology Park, No. 21 Bulan Road, Nanwan Street, Longgang District, Shenzhen City, Guangdong Province