In the field of current collector for batteries, functional coating is proven to be a breakthrough technology Surface coating of Al foil with one or more conductive materials exhibits two-dimensional or multidimensional conductive networks. According to theoretical simulation and experimental results, the coating technology is optimized. Compared to state-of-the-art modified aluminum foil, the functional coating prepared by our technology has thinner thickness, lower resistance and enhanced adhesion. Consequently, the electrochemical performance could be improved effectively with the modified AL foil. Moreover, the cost of production and use can reduced.

| Model Number |

NS-CCAF001 |

| Place of Origin |

Shenzhen, China |

| Brand Name |

Nsfoil |

| Product Name |

Carbon Coated Aluminum Foil Collecting Fluid |

| Usage |

Lithium Battery |

| Application |

Electronic, New Energy |

| Feature |

Thin, High Stability |

| Material |

carbon, aluminum foil, copper foil |

| Advantage |

Excellent static conductivity, reduce the contact resistance |

| Sample |

Sample Offered |

| Packing |

Carton or as request |

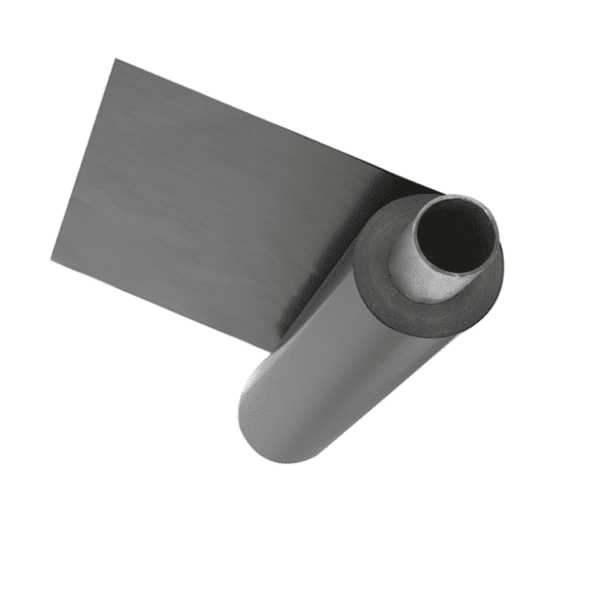

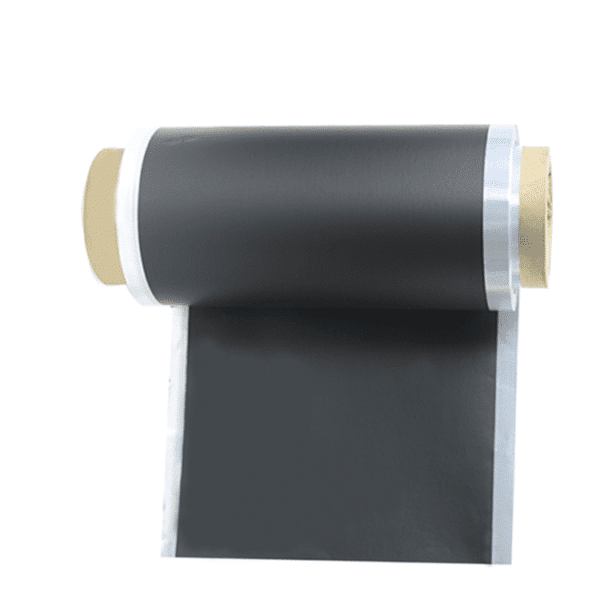

Product properties

Color: black, gray

Base material: aluminum foil, copper foil

Base material thickness: 10-20 μm

Coating method: single coating, double coating

Effective coating width: customized

Material width: customized

Inner diameter of pipe core:76mm

Packing: wooden case

Origin: Foshan

Application

◎ Lithium-ion batteries for electric vehicle and energy storage(LFP、LMFP、LMO、NCM、NCA、LNM、LTO)

◎ Lithium-ion batteries for 3C productions(LCO、LMO)

◎ Supercapacitor

◎ Lithium-ion capacitor

◎ Lithium ion battery in water system

◎ Alkaline batteries

Advantage

◎ Improve the surface tension and increase the adhesion Lithium-ion batteries for electric vehicles between the Al foil and the active material.

◎ Decrease the using amount of binder for the electrode, enhance energy density of the battery ,and lower the cost of the electrode production.

◎ Protect the Al current collector from surface corrosion and oxidation.

◎ Reduce interfacial resistance and internal resistance of the cell.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise Lithium ion battery in water system the pass rate of the cell; Increase the consistency and cycling life of the cell and lower the cost of the production