|

Grade

|

1-8Series

|

|

Temper

|

0-H112

|

|

Type

|

Foil

|

|

Application

|

Lithium Battery Anode

|

|

Width

|

500mm-2800mm

|

|

Surface Treatment

|

Coated

|

|

Alloy Or Not

|

Is Alloy

|

|

Place of Origin

|

China

|

|

Province

|

Shenzhen

|

|

Brand Name

|

NSfoil

|

|

Model Number

|

NSAF8011

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, Decoiling, Welding, Punching, Cutting

|

|

Delivery Time

|

8-14 days

|

|

Product name

|

Aluminum Foil Al Foil for Lithium Battery Anode Current Collector

|

|

Keyword

|

Aluminum foil

|

|

MOQ

|

3 Tons

|

|

Color

|

Customized Color

|

|

Surface

|

Smooth

|

|

Length

|

Customized length

|

|

Package

|

Strong Sea Worthy Wooden Package

|

|

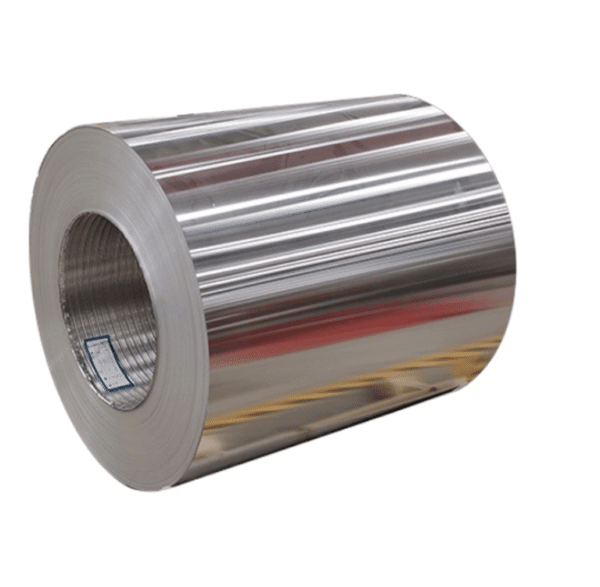

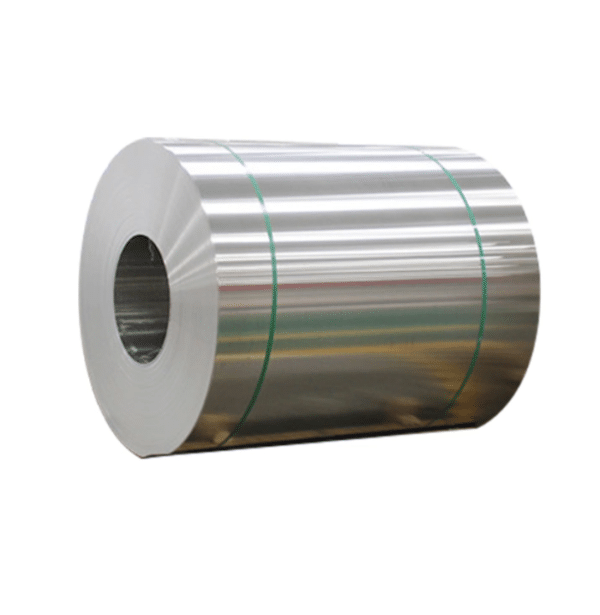

Shape

|

Roll

|

|

Size

|

Customized size

|

|

Sample

|

Freely

|

Aluminum Foil for Lithium Battery Anode Current Collector

Our Aluminum foil has become an excellent material choice for lithium battery anode current collectors, contributing to efficient and dependable operation of lithium-ion batteries in various applications.

Features

Our Aluminum foil is often utilized as a current collector material in lithium-ion battery anodes due to its unique advantages. Here are a few key points regarding using aluminum foil as an anode current collector:

1. Lightweight: Aluminum foil’s lightweight properties allow it to decrease overall battery weight, making it more suitable for portable devices or applications where weight may be an issue.

2. Outstanding Conductivity: Aluminum’s exceptional electrical conductivity allows it to efficiently collect current from battery active materials, providing for smooth flow of electrons during charge and discharge cycles and therefore improved battery performance.

3. Aluminum Foil With High Surface Area: Aluminum foil can easily be manufactured to have a large surface area, creating sufficient contact between electrode active material and current collector for effective electron transfer. This facilitates better adhesion between materials as well as improved electron transfer efficiency.

4. Corrosion Resistance: Aluminum foil provides unparalleled corrosion resistance, helping ensure long-term battery stability and reliability. This feature can prevent side reactions from taking place while upholding structural integrity within an anode’s anode structure.

5. Flexibility: Aluminum foil’s flexibility makes it suitable for use in many battery designs and manufacturing processes, including flexible battery designs such as flip top batteries. It can easily be folded, laminated or otherwise altered to allow greater design flexibility and adaptability.

6. Cost-Effectiveness: Aluminum foil is relatively economical among metal foils, making it an economical solution for large-scale battery production.

Our Aluminum foil has become an excellent material choice for lithium battery anode current collectors, contributing to efficient and dependable operation of lithium-ion batteries in various applications.

Related products

-

Industry Foil

Molecular Sieve Aluminum Foil MSAL

-

Industry Foil

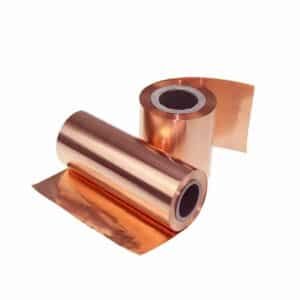

600mm Wide 0.05mm-0.06mm Thin Pure Copper Tape Foil