An Introduction to Lithium-ion Batteries and Need for Effective Current Collectors.

Lithium-ion batteries have become an integral part of modern life, from smartphones and electric vehicles to personal computing. But have you ever stopped to wonder what goes into making lithium-ion batteries so powerful and reliable? A key element that contributes significantly is current collector material – one component which plays an essential role in their success is this keystone technology.

In this blog post, we will delve into the mysterious world of copper foil as an effective current collector material in lithium-ion batteries. We will investigate its properties, advantages, challenges and limitations as well as recent research studies that shed light on its possible future developments. Get ready for an electrifying adventure as we unearth its mysteries!

What Are Copper Foil Properties and Uses?

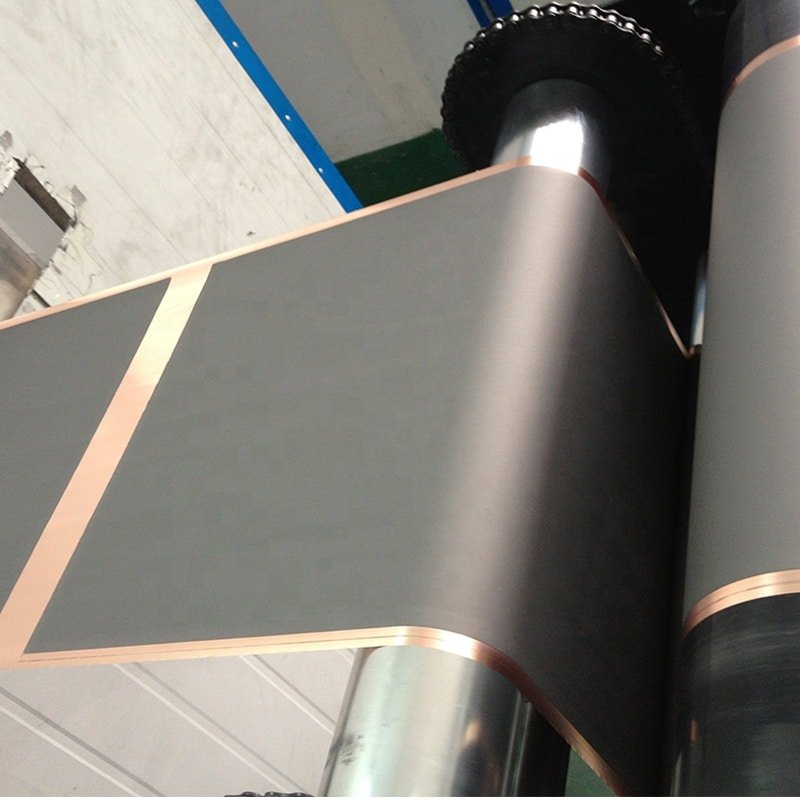

Copper foil is an economical and effective current collector material used in lithium-ion batteries. Due to its excellent electrical conductivity, copper foil provides efficient electron circulation within the battery pack.

One of the primary features of copper foil is its excellent conductivity, enabling low resistance and minimal energy loss during charge and discharge cycles – contributing significantly to improving lithium-ion battery performance overall.

Copper foil not only exhibits excellent conductivity but also has impressive flexibility, enabling it to be easily bent or shaped to suit various battery designs. Due to its malleability, copper foil fits seamlessly into various electrode configurations while maintaining optimal contact between active materials and the current collector.

Copper foil offers excellent thermal stability, making it suitable for applications where batteries may experience high operating temperatures or rapid temperature changes without experiencing significant degradation. This quality makes copper foil an invaluable choice.

Copper foil offers excellent corrosion resistance against common electrolyte solutions used in lithium-ion batteries, providing long-term reliability and durability of current collector material.

Copperfoil stands out as an exceptional current collector material for lithium-ionbatteries due to its combination of electrical conductivity, flexibility, thermal stability and corrosion resistance.

Advantages of Copper Foil as a Current Collector in Lithium-ion Batteries

Copper foil has become an increasingly popular current collector material choice for lithium-ion batteries due to its many advantages. Copper offers exceptional electrical conductivity, which ensures efficient charge and discharge cycles while its low resistivity allows electrons to flow smoothly during operation.

Copper foil boasts exceptional thermal conductivity properties, helping dissipate heat generated during battery usage and prevent overheating or potential cell damage. Copper’s capacity to efficiently manage temperature fluctuations makes it an excellent choice for high performance applications where safety and longevity are of utmost importance.

Copper foil’s malleability and ductility also makes it an attractive material choice, as its properties allow it to be easily formed into thin sheets or foils without compromise to its structural integrity. As a result, manufacturers can seamlessly incorporate copper foils into battery electrodes construction for optimal contact between active materials and collectors.

Copper also exhibits excellent corrosion-resistance when exposed to electrolytes commonly found in lithium-ion batteries, ensuring that current collectors remain stable over extended periods of use and providing optimal performance throughout their battery’s lifespan.

Copper foil is readily available and cost-effective compared to alternative current collector materials like aluminum or nickel, making it an economical and sustainable solution for mass production of lithium-ion batteries at the same time.

Copper foil has become increasingly popular as a current collector material in lithium-ion batteries due to its excellent electrical conductivity, thermal management capabilities, malleability and corrosion resistance properties – qualities which combine together for greater overall battery performance enhancement. Its affordability also makes copper an appealing option when looking to increase overall battery performance.

Challenges and Limitations of Copper Foil in Battery Applications

Copper foil is often utilized as a current collector material in lithium-ion batteries due to its superior electrical conductivity and low resistivity, but this solution comes with its own set of obstacles and restrictions.

One major difficulty lies with corrosion. Copper’s propensity to oxidize when exposed to moisture or certain chemicals found within battery environments can result in the formation of copper oxide layers on its surface and hinder electron transfer, increasing resistance and decreasing electron transfer speed. Manufacturers have developed various coating techniques and protective layers in order to address this issue.

Another challenge related to mechanical stability. Copper foil must be flexible while remaining strong enough not to collapse under stress during battery assembly or operation, and finding an optimal balance between thickness and strength may prove challenging.

Copper foil production presents challenges related to uniformity. To ensure proper functioning within battery cells, its surface should ideally have no defects that disrupt current flow; maintaining consistent quality throughout large-scale production remains an ongoing goal.

Copper foil may be limited by cost as a current collector material, particularly as demand for lithium-ion batteries increases and ensures more widespread adoption is necessary. With such low access costs it becomes vitally important that widespread adoption occurs.

While research and development efforts continue to address these challenges and limitations, innovative solutions such as alternative materials, advanced manufacturing techniques, and enhanced coatings are constantly being explored to maximize copper foil as an efficient current collector material in future battery applications. Continuous advancement will lead to an increase in its potential as an efficient current collector material.

Research Studies of Copper Foil Applications in Lithium-ion Batteries

Recent research studies have been undertaken to investigate the use of copper foil as a current collector material in lithium-ion batteries. These studies aim to gain an understanding of its performance and potential advantages within battery applications.

One research study investigated the effects of various copper foil thicknesses on battery performance. Results of this research demonstrated that thinner copper foils led to improved electrode adhesion and reduced internal resistance resulting in enhanced battery efficiency.

Studies on various surface modifications on copper foils investigated their effect on electrochemical properties, and in turn battery performance. By changing surface morphology and composition, researchers were able to improve conductivity and stability thereby ultimately increasing overall battery performance.

Research has also explored novel manufacturing techniques for producing high-quality copper foils with enhanced properties, such as electroplating and annealing processes that can increase grain size distribution while simultaneously decreasing defects within their foil structures.

Research studies such as these underscore the significance of studying how factors such as thickness, surface modifications and manufacturing techniques impact copper foil current collector performance for lithium-ion batteries. Further exploration in these areas will surely contribute to advancements in battery technology.

Copper Foil as Current Collection Material – Future Potential and Development

Copper foil as a current collector material in lithium-ion batteries shows great promise for future advancement. Researchers and scientists are currently exploring ways to increase its properties while also finding solutions to any limitations it might present.

One area of focus for copper foil improvements is increasing its electrical conductivity. By doing so, copper foil can collect and transport current within battery systems more effectively for improved overall performance – leading to increased energy storage capacity as well as quicker charging times for lithium-ion batteries.

Copper foil durability is being investigated extensively as batteries undergo constant charge-discharge cycles, necessitating materials that can withstand this repetitive stress without degrading over time. Scientists are developing protective coatings or alloys which will extend its longevity for long-lasting battery applications.

Researchers are exploring more sustainable alternatives to copper foils. With environmental concerns increasing, finding eco-friendly materials becomes ever more essential. Some studies have explored using recycled or alternative forms of copper as current collectors to reduce reliance on virgin materials while maintaining performance standards.

Manufacturing techniques hold tremendous promise for further improving copper foils as current collectors. Electroplating or nanofabrication methods may offer precise control over thicknesses and surface structures of foils, further optimizing their effectiveness.

Copper foil research holds enormous promise as an alternative current collector material, offering tremendous promise for advanced lithium-ion battery technology. By exploring conductivity improvements, durability improvements, sustainable alternatives exploration and innovative manufacturing techniques – we anticipate seeing significant breakthroughs that could revolutionize battery technology across a wide variety of industries from electric vehicles to renewable energy systems.

Conclusion

Copper foil has proven itself as an indispensable and efficient current collector material in lithium-ion batteries, thanks to its exceptional properties such as high conductivity, flexibility, and corrosion resistance. By collecting and disbursing electric current within the battery effectively, copper foil helps improve overall battery performance and reliability.

Copper foil offers many advantages; however, there are certain drawbacks which must be addressed as well. Issues such as dendrite formation and mechanical failure in extreme conditions present challenges to its long-term use as battery applications; however, ongoing research studies are being conducted in order to overcome such hurdles and enhance copper foil’s performance as a current collector material.

Future prospects of copper foil as a current collector material offer immense promise. Thanks to advances in materials science and engineering techniques, researchers are exploring methods of optimizing its properties by changing its structure or alloying it with other metals; such innovations aim at improving stability, preventing dendrite growth, increasing energy density density density density density density density as well as prolonging lithium-ion battery lifespans.

Copper foil’s role as a current collector material in lithium-ion battery technology advancement cannot be overemphasized. Its exceptional electrical conductivity combined with its versatility make it an excellent solution for efficiently collecting and disbursing current within batteries. As we pursue more powerful yet sustainable energy storage solutions, further advancements using copper foil will likely play a pivotal role in shaping its future development.