Introduction to Lithium-ion Batteries (LIBs)

Welcome to our blog where we explore the fascinating world of lithium-ion batteries and explore their vital role as current collectors in improving performance. As technology has advanced quickly, these powerful rechargeable powerhouses have become essential components in vehicles like electric vehicles as well as portable electronics devices.

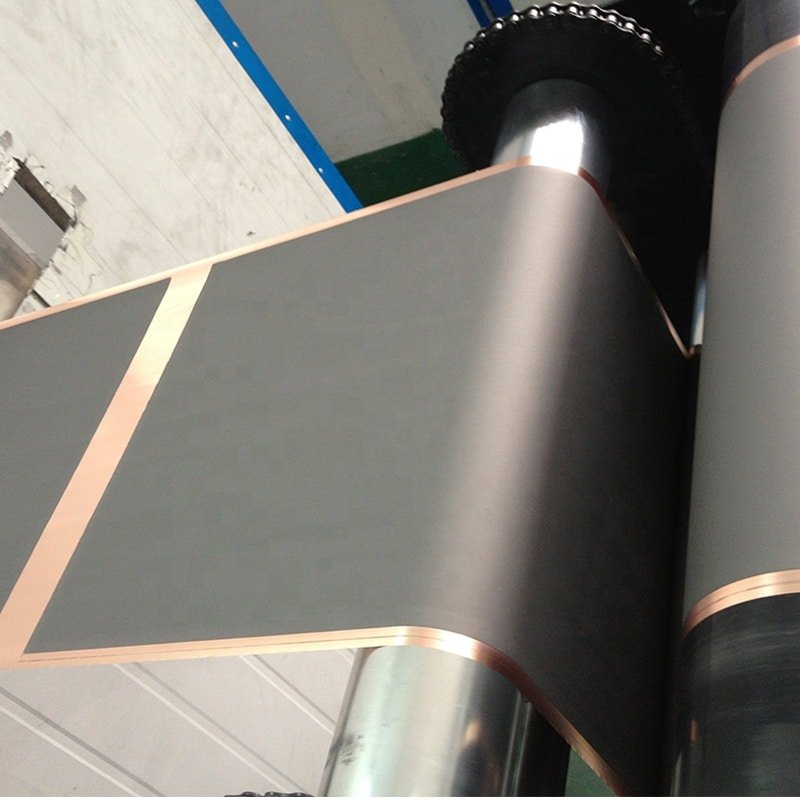

But what exactly are current collectors? Consider them as the cornerstone of any lithium-ion battery: their job is to efficiently transfer electrical charges between active electrode material and external circuit. Simply put, current collectors ensure your battery functions optimally and delivers reliable power when you need it most.

In this article, we’ll conduct a comparison between copper and aluminum as current collector materials. Each has unique advantages and drawbacks that can impact battery performance in terms of efficiency, lifespan, cost-efficiency and overall lifespan – so let’s dig further into this exciting subject matter to uncover which material holds the key to unlocking future innovations in energy storage technology!

Importance of Current Collectors for Battery Performance

Current collectors play an essential part in lithium-ion battery performance and efficiency, playing an instrumental role in their overall effectiveness and overall performance.

Current collectors serve as conducting pathways within batteries, facilitating electron flow between electrodes and external circuitry. Their function is to collect and distribute electrical current evenly across electrode surfaces in order to ensure optimal charging and discharging processes.

Copper and aluminum are two popular choices when selecting current collector materials, offering great conductivity but are more costly compared to their aluminum counterparts. Aluminum provides more cost-effective solutions but has slightly reduced conductivity compared to copper.

Selecting an effective current collector material depends on several considerations, such as specific energy requirements, operational conditions, and cost considerations. Selecting an ideal current collector material can have significant effects on battery performance, lifespan and overall cost-effectiveness.

Efficiency can be enhanced when there is minimal resistance in electron transfer between electrodes through effective current collector materials, ensuring maximum power delivery during discharge cycles with reduced energy losses during charging cycles.

Lifespan of current collector materials is another key consideration. High-grade materials with superior corrosion resistance help minimize degradation over time due to chemical reactions or physical wear-and-tear.

Cost plays a key role in commercial applications that involve mass production. Selecting an affordable yet efficient material helps lower battery costs without compromising performance standards.

Researchers continue to explore novel methods of improving current collector materials or creating entirely new options that offer better conductivity while remaining both environmentally sustainable and economically feasible.

Understanding the significance of selecting suitable current collector materials for lithium-ion batteries cannot be overemphasized. Their performance, efficiency levels and ultimate success in meeting various energy storage needs across industries depends heavily on these selections.

Comparison Between Copper and Aluminum as Current Collector Materials

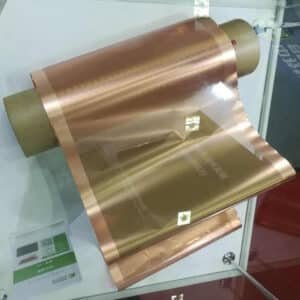

Copper and aluminum are popular choices when selecting current collector materials for lithium-ion batteries, each having unique advantages and disadvantages that make them suitable for different battery applications.

Copper has long been used as a current collector material due to its exceptional electrical conductivity, enabling efficient electron transfer within batteries for better overall performance. Furthermore, its thermal conductivity helps dissipate heat generated during charging and discharging processes, further aiding its use as a current collector material.

Aluminum has quickly gained in popularity as a current collector material due to its lightweight nature. Aluminum provides significant weight reduction when compared with copper, making it suitable for portable electronic devices requiring lighter batteries and being both abundant and more cost-effective than copper.

However, both materials have drawbacks that must be considered. Copper may be susceptible to corrosion under certain battery chemistries and operating conditions and lead to reduced lifespan and efficiency; on the other hand, aluminum has lower electrical conductivity which may impact overall battery performance.

Comparing copper and aluminum as current collector materials for lithium-ion batteries reveals each material has unique advantages and disadvantages that must be considered when selecting one over the other. Decisions between them depend on factors like specific application requirements (weight vs conductivity), budget constraints, cost-effectiveness considerations, compatibility with battery chemistries (corrosion resistance) etc.

Advantages and Disadvantages of Copper Current Collectors

Copper current collectors play a vital role in lithium-ion battery performance. Let’s explore some advantages and disadvantages associated with using copper as a current collector material.

Advantage 1: High Electrical Conductivity

Copper has an outstanding electrical conductivity that allows for efficient electron transfer within batteries and maximizes energy storage and discharge capabilities, helping to minimize internal resistance for improved overall battery efficiency. Copper also offers antimicrobial properties which protect it against corrosion that might otherwise corrode over time, further contributing to its positive attributes.

Advantage 2: Excellent Thermal Conductivity

Copper current collectors offer another advantage by virtue of their outstanding thermal conductivity, which allows effective heat dissipation during battery operation, thus preventing overheating issues which could compromise battery performance or pose safety threats.

Disadvantage 1: Corrosion Susceptibility

However, one drawback of using copper as a current collector material is its susceptibility to corrosion. When exposed to certain electrolytes or environmental conditions, copper may corrode over time, which can increase resistance and shorten battery lifespan unless appropriately managed through protective coatings or design modifications.

Disadvantage 2: Higher Cost

Copper current collector material typically commands a higher cost compared to aluminum due to factors like raw material availability and manufacturing complexity; this price difference could impact lithium-ion battery affordability for specific applications.

Noting the advantages and disadvantages associated with copper current collectors is crucial, but should be evaluated against specific application needs as well as potential trade-offs between performance and costs. Future studies in materials science engineering could address some limitations encountered by using copper.

Advantages and Disadvantages of Aluminum Current Collectors

Advantages of Aluminum Current Collectors

aluminum has its advantages when used as a current collector material in lithium-ion batteries, yet there can still be drawbacks associated with using it as current collector material. A key drawback of aluminum’s lower electrical conductivity compared to copper may lead to higher resistive losses within the system and decrease overall energy efficiency.

Aluminum’s low melting point renders it susceptible to thermal issues during high-current charging or discharging processes, creating heat which can lead to deformation or failure of current collectors themselves.

Aluminum may form thicker surface films when exposed to electrolytes used in lithium-ion batteries, preventing proper ion transport between electrodes and ultimately hindering overall battery performance.

Disadvantages of Aluminum Current Collectors

Aluminum Current Collectors offer several advantages over their steel counterparts. However, there are a few drawbacks of using Aluminum current collectors which you should know about before investing.

Aluminum may offer many advantages as a current collector material in lithium-ion batteries; however, there are also drawbacks associated with using it as current collector material. One major drawback of aluminum as current collector material lies in its lower electrical conductivity relative to copper; this can cause higher resistive losses within the battery system and consequently decrease energy efficiency.

Aluminum’s lower melting point compared to copper makes it more susceptible to thermal issues when charging or discharging high current, leading to excessive heat being generated during charging or discharging processes. Under such conditions, deformation and even failure of current collectors may occur as a result.

Aluminum may also pose limitations when exposed to lithium-ion battery electrolytes, as this material tends to form thicker surface films which impede proper ion transport between electrodes and hamper overall battery performance.

In summary,Aluminum has many advantages when used for current collectors in lithium-ion batteries, such as its lightweight design and corrosion resistance properties; however, its electrical conductivity and thermal stability limitations must also be carefully considered when selecting materials to maximize performance and extend battery lifespan. Manufacturers must make an informed choice to select optimal battery materials to achieve maximum battery performance and longevity.

Impact on Battery Performance: Efficiency, Lifespan and Cost

Copper and aluminum both present unique benefits when selecting current collector materials for use in lithium-ion batteries, in terms of efficiency, lifespan and cost considerations.

Efficiency is an integral component of battery performance. Copper current collectors are known for their superior electrical conductivity, which facilitates effective electron transfer during charge and discharge cycles, leading to lower internal resistance and greater overall energy efficiency. On the other hand, aluminum offers slightly less electrical conductivity compared to copper but possesses superior thermal conductivity which allows heat dissipation more effectively during operation, improving overall efficiency.

Lifespan is another key factor when considering battery performance. Copper current collectors offer superior corrosion resistance, making them highly long-lived over time. Furthermore, their mechanical strength reduces risks related to physical damage that could threaten longevity. Although aluminum collectors may not offer equal corrosion resistance as copper ones, they still can offer sufficient lifespan when coated or protected from harsh environments.

Cost can often be the determining factor when selecting current collector materials for lithium-ion batteries. While copper typically costs more due to higher material and processing requirements, its superior electrical conductivity and durability characteristics could provide long-term cost savings through improved battery performance and reduced maintenance needs.

In a word, copper and aluminum both offer their own set of benefits when used as current collector materials in lithium-ion batteries, including impacts such as efficiency, lifespan, cost.

Future Perspective of Lithium-ion Battery Collecting Materials

Technology continues to advance and the pursuit of more efficient and cost-effective materials for lithium-ion battery components is an ongoing effort. One area in particular where this search takes place is current collector materials – they play an integral part in battery performance – often using copper and aluminum; however, researchers are exploring alternatives which could potentially revolutionize this industry.

One promising material under investigation is graphene. Due to its remarkable conductivity and strength, graphene-based current collectors could provide significant improvements in battery efficiency by reducing resistance and increasing energy density. Furthermore, its high surface area may improve electrode adhesion thereby improving cycling stability.

Carbon nanotubes (CNTs) have recently received significant attention. Thanks to their excellent electrical conductivity and mechanical properties, CNT-based current collectors provide benefits including enhanced charge/discharge rates and increased overall capacity. Furthermore, CNTs can easily integrate into manufacturing processes.

Metal oxides such as titanium dioxide (TiO2) are currently being considered as potential current collector materials of the future. TiO2 has demonstrated its promise as an antidentrite agent during battery charging cycles, offering significant increases in safety.

Alongside developing new materials, researchers are also investigating innovative designs for current collectors. Three-dimensional porous structures created through electrospinning or additive manufacturing methods like 3D printing provide more active surface area to improve ion transfer kinetics while decreasing resistance within battery systems.

Alternative materials have shown great promise in laboratory settings, yet there remain several challenges they must overcome in order to be implemented into commercial lithium-ion batteries. Scalability of production methods, cost effectiveness compared with traditional materials like copper or aluminum and long-term stability under various operating conditions must all be carefully considered prior to widespread implementation of such alternatives in commercial applications.

Overall, lithium-ion battery collector materials appear promising for future applications. Through continued research and development efforts, more innovative materials may emerge that offer even better battery performance.

Conclusion:

From our comparative analysis of current collector materials for lithium-ion batteries, it is apparent that both copper and aluminum present their own set of advantages and disadvantages.

Copper current collectors provide excellent conductivity, low resistance and mechanical strength – qualities which make them particularly suitable for applications requiring high power output and fast charging/discharging rates. Unfortunately, copper does come with its own set of drawbacks such as higher costs, potential corrosion issues under certain conditions and weight.

Aluminum current collectors offer an economical alternative, featuring lightweight construction with lower costs compared to copper versions. Aluminum’s superior thermal stability outshines copper’s shortcomings in electrical conductivity and mechanical strength, making these current collectors ideal for applications where weight reduction or cost efficiency are top considerations.

Copper or aluminum current collector materials depend upon specific battery needs and design considerations, with efficiency, lifespan and overall performance depending on which material is chosen as current collector material.

Researchers in this field are actively exploring alternatives materials to copper and aluminum that could overcome some of their limitations, including carbon-based nanomaterials such as graphene or carbon nanotubes with high electrical conductivity while remaining lightweight.

As energy storage technology continues to advance quickly, more advancements should address existing collector material challenges in order to further increase battery efficiency and enhance battery performance.