| Producer | NSfoil |

| Country of Origin | China |

| Packaging | Wooden Box |

| Diameter, mm | 2.0-3.5 |

| Nozzle type | Molecular Sieve |

| Static water adsorption, % | 22 ± 3 (25°С, RH=55%, 24g) |

| Water content, % | 2 ± 1 |

| Hardness, N | 40 ± 20 |

| Zeolite (Anhydrous Solids Content, 1h/800°С), % | 80 ± 3 |

| Binder, % | 18 ± 2 |

| Bulk density, g/l | 730 ± 70 |

| Application | desorber, absorber, distillations, rectifications, packed columns, decarbonizer, gas purification, dehydration |

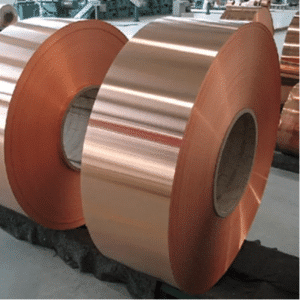

Molecular sieve aluminum foil is a special type of aluminum foil that has been impregnated with a molecular sieve material. Molecular sieves are synthetic zeolites, which are porous materials that allow for the separation of molecules based on their size, shape, and polarity. The molecular sieve material used in the aluminum foil is typically a zeolite with a high surface area and microporous structure, which allows it to selectively adsorb small molecules such as water, carbon dioxide, and other gases.

The main purpose of molecular sieve aluminum foil is to provide a moisture barrier for the products that it packages. Moisture can be a significant problem for many products, including pharmaceuticals, medical devices, electronics, and food. If these products are exposed to moisture, it can cause degradation, corrosion, and loss of functionality. By using molecular sieve aluminum foil, the products can be protected from moisture and maintain their quality.

The molecular sieve aluminum foil is typically manufactured by coating the aluminum foil with a layer of molecular sieve material and then adding a polyethylene coating to provide additional moisture protection. The resulting product is a highly effective moisture barrier that can be used in a wide range of applications.

Overall, molecular sieve aluminum foil is an important material for many industries that require moisture protection for their products. Its unique properties make it an effective solution for protecting sensitive products from the harmful effects of moisture.