Features

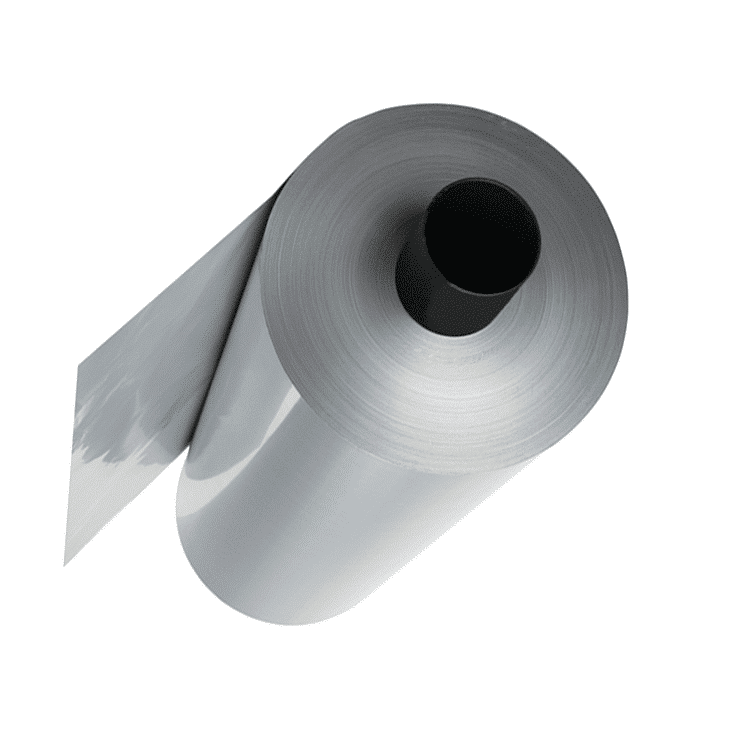

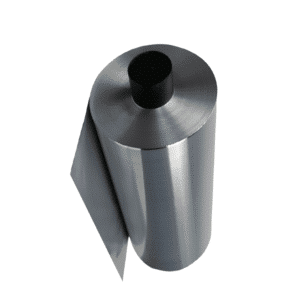

Etched cathode foil, commonly called structured cathode film or patterned cathode foi, is a specific material that is used to make lithium-ion batteries. It is distinguished by its distinct characteristics and advantages, such as:

1. More active material utilization The cathode foil etched with a microstructured, smooth surface usually with micron-sized pits or channels. This microstructure facilitates better deposition and adherence of the cathode’s active material, resulting in greater the utilization of material active. This means that the battery is able to provide more capacity and a higher energy density.

2. Enhanced electrode-electrolyte interaction: The microstructured surface of the etched cathode foil provides a larger surface area for electrode-electrolyte interaction. The increased surface area allows for quicker diffusion of ions and increases the electrochemical performance overall that the batteries provide. It allows for efficient discharge and charge rates, increasing the performance that the batteries can provide.

3. Increased stability in cycling The microstructure of the cathode’s foil is etched to help reduce strain and stress in charging and discharge cycles. It allows for growth and contraction in the materials used, thus reducing the possibility of deterioration of electrodes and increasing the cycle stability that the batteries. This feature can lead to a longer battery life and a longer lasting.

4. Increased rate capability: The etched cathode foils allow for greater rates of lithium-ion batteries. The microstructured surface permits rapid diffusion and transport of ions in the electrode which allows batteries to handle the demands of high current. This feature is crucial in applications that require rapid charging or discharging like electric vehicles and portable electronic devices.

5. Contact resistance is low The microstructured layer of the cathode foil that has been etched improves contacts between the material active and collector. This enhanced contact decreases resistance of the contact, reducing energy losses and enhancing the overall efficiency of the battery. It assists in maintaining a excellent electrical conductivity as well as improve the performance of the battery.

6. Customization: The cathode foil that is etched can be customized to satisfy specific specifications for battery designs. The shape, size, and the pattern of the microstructure may be altered to enhance the electrochemical efficiency for the electrode. This flexibility permits the creation of batteries that have desired characteristics, for example, high energy density or high power density or with specific capability to cycle.

7. Integration into the existing processes for manufacturing: The etched cathode foils are able to be incorporated into existing processes for manufacturing batteries without significant changes. This allows for scalability and cost-effectiveness of the production of lithium-ion batteries.

8. Benefits for the environment: Through enhancing the utilization of active materials in battery production, etched cathode film aids in reducing overall consumption of materials and waste produced by the production of batteries. It helps in the creation in more eco-friendly and eco sustainable energy storage solutions.

The Etched cathode is an exciting technique which addresses the shortcomings of cathode material used in conventional lithium-ion batteries. Its unique characteristics make it a compelling choice to enhance battery performance as well as making it possible to make advances in various applications like electric vehicles and renewable energy systems and portable electronic devices.

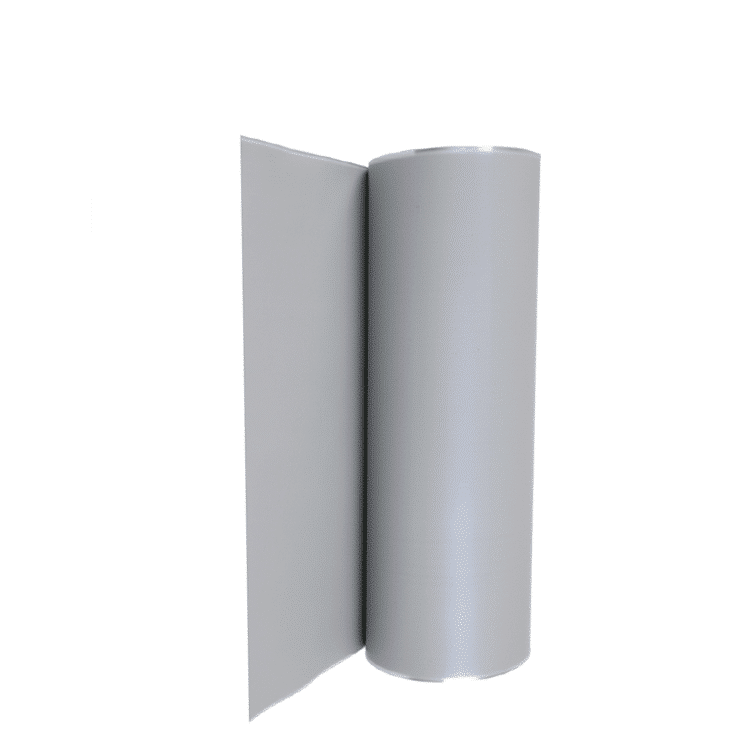

Advantages

◎ Improve the surface tension and increase the adhesion Lithium-ion batteries for electric vehicles between the Al foil and the active material.

◎ Decrease the using amount of binder for the electrode, enhance energy density of the battery ,and lower the cost of the electrode production.

◎ Protect the Al current collector from surface corrosion and oxidation.

◎ Reduce interfacial resistance and internal resistance of the cell.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise Lithium ion battery in water system the pass rate of the cell; Increase the consistency and cycling life of the cell and lower the cost of the production